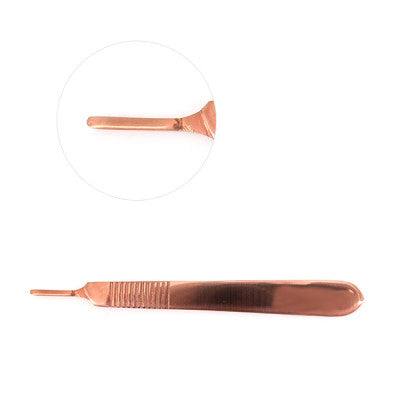

What is a No. 3 Surgical Knife Handle (Colour Coated)?

The No. 3 surgical knife handle is the common standard used to hold small surgical knives (typically sizes 10-15). While the standard polished stainless-steel finish remains the most common, colour-coated versions provide a contemporary solution for surgical teams seeking to organise their instruments and identify sets of instruments or decrease glare when using the high-intensity operating room lighting. 1

These handles are constructed from stainless steel of medical grade, and then coated with a tough biocompatible coating that can withstand the most rigorous sterilisation procedures. 2

Key Features of the Colour Coated No. 3 Handle

-

Precision Fit: Specially designed to lock securely No. 10, 11, 12 or 15 blades securely in place and ensure zero "blade play" during delicate incisions.3

-

Ergonomic design: Features a slim, flat profile that has an ergonomically textured or ribbed grip zone to give maximum grip and stop sliding, even if wearing wet gloves. 4

-

High-Durability coating: The specially-designed colored layer (often ceramic or PTF-based) is impervious to corrosion, chipping and autoclaving repeatedly. 5

- Anti-Glare Finish Contrary to mirror-like stainless steel, colored handles assist in reducing eye fatigue for surgeons by reducing the reflection of light.

Why Choose Colour Coated Handles?

1. Rapid Identification

In a highly-spaced Operating Room (OR) in a fast-paced OR, colour codes allow the surgeon to determine the appropriate surgical instrument quickly. 6 You can assign the colours according to:

- Department: (e.g., Blue for Plastics, Gold for Cardiology).

- Blade Type (e.g., green handles always have one blade of the number 11).

- Surgeon Preferences: Personalising sets for certain doctors.

2. Organisational Efficiency

Color coded codes make it easier to "count" and tray assembly within the Sterile Processing Department (SPD). It helps ensure that handles remain within their set of designated handles and reduces the time trying to sort through the trays with different instruments.

3. Enhanced Safety

A clear distinction in visuals between different scalpel configurations decreases the chance of giving the wrong size blade at the time of surgery, improving the overall safety of patients.

Technical Specifications & Compatibility

Specification Details

Material High-Grade Medical Stainless Steel

Compatible Blades #10, #11, #12, #12d, #13, #14, #15, #15c

Length approximately 12cm (Standard No. 3 length)

Sterilization Autoclavable / Gamma / EtO Compatible

Coating Options : Gold, Blue, Black, Rainbow (Plasma), or Green

Care and Maintenance

To ensure the long-term durability of the colour coating as well as the structure of the hand:

- Cleaning : Make use of pH-neutral detergents to avoid stripping the colour.

- Avoid Abrasives : Avoid using steel wool or Abrasive brushes on the surface.

- Check: Regularly check the "fitting" end of the handle for signs of wear and tear to ensure the blades remain in their place with utmost security.

- Autoclaving : Utilise standard hospital guidelines regarding stainless steel equipment. Top-quality coatings are designed to withstand temperatures as high as 130 °C (273degF).